- Home

- Medical news & Guidelines

- Anesthesiology

- Cardiology and CTVS

- Critical Care

- Dentistry

- Dermatology

- Diabetes and Endocrinology

- ENT

- Gastroenterology

- Medicine

- Nephrology

- Neurology

- Obstretics-Gynaecology

- Oncology

- Ophthalmology

- Orthopaedics

- Pediatrics-Neonatology

- Psychiatry

- Pulmonology

- Radiology

- Surgery

- Urology

- Laboratory Medicine

- Diet

- Nursing

- Paramedical

- Physiotherapy

- Health news

- Fact Check

- Bone Health Fact Check

- Brain Health Fact Check

- Cancer Related Fact Check

- Child Care Fact Check

- Dental and oral health fact check

- Diabetes and metabolic health fact check

- Diet and Nutrition Fact Check

- Eye and ENT Care Fact Check

- Fitness fact check

- Gut health fact check

- Heart health fact check

- Kidney health fact check

- Medical education fact check

- Men's health fact check

- Respiratory fact check

- Skin and hair care fact check

- Vaccine and Immunization fact check

- Women's health fact check

- AYUSH

- State News

- Andaman and Nicobar Islands

- Andhra Pradesh

- Arunachal Pradesh

- Assam

- Bihar

- Chandigarh

- Chattisgarh

- Dadra and Nagar Haveli

- Daman and Diu

- Delhi

- Goa

- Gujarat

- Haryana

- Himachal Pradesh

- Jammu & Kashmir

- Jharkhand

- Karnataka

- Kerala

- Ladakh

- Lakshadweep

- Madhya Pradesh

- Maharashtra

- Manipur

- Meghalaya

- Mizoram

- Nagaland

- Odisha

- Puducherry

- Punjab

- Rajasthan

- Sikkim

- Tamil Nadu

- Telangana

- Tripura

- Uttar Pradesh

- Uttrakhand

- West Bengal

- Medical Education

- Industry

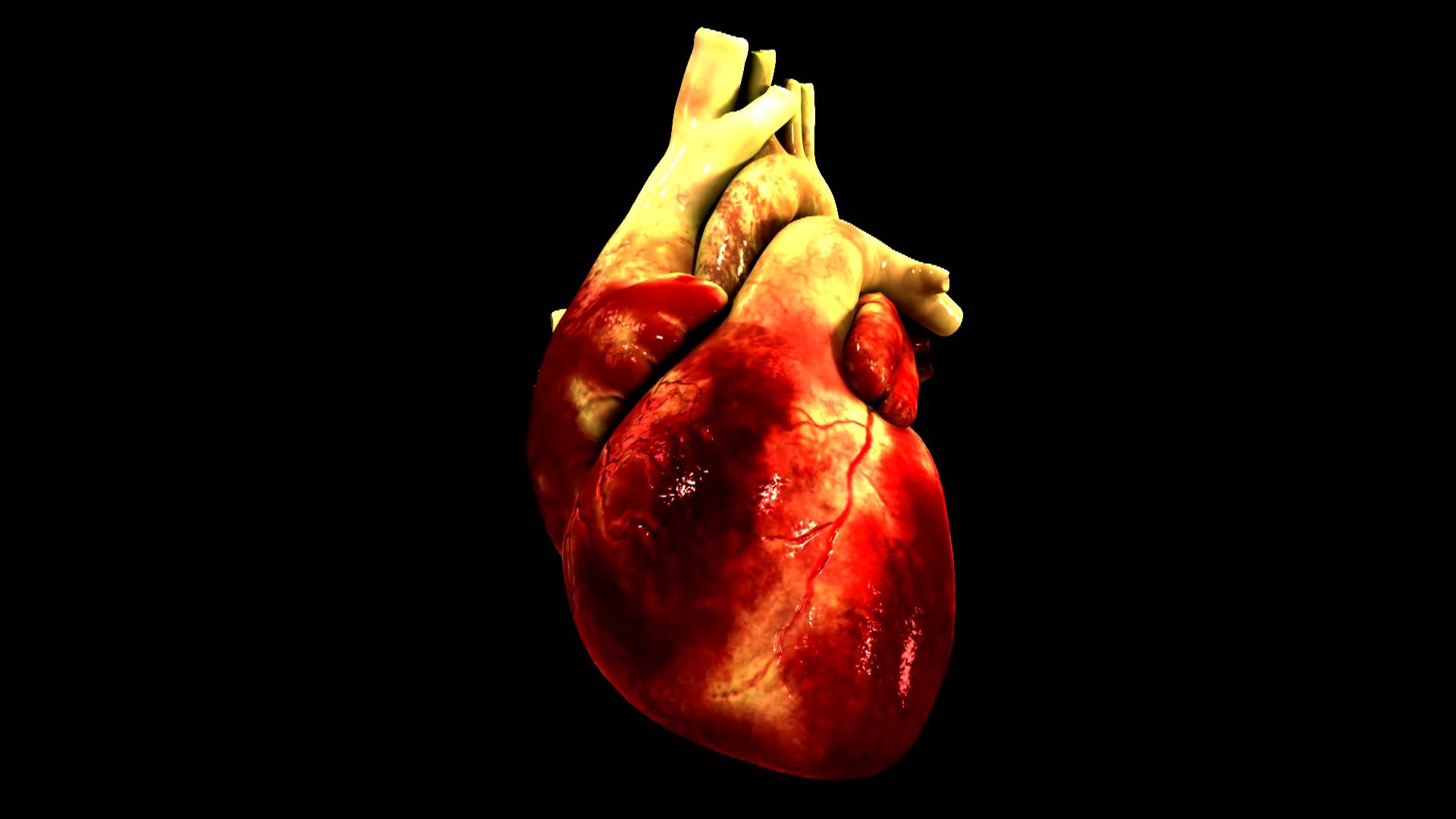

3D models of heart, arteries created

WASHINGTON: Researchers have used a new inexpensive 3D printing method to develop models of heart and arteries out of biological materials. The advance could one day lead to a world in which transplants are no longer necessary to repair damaged organs, researchers said.

"We've been able to take MRI images of coronary arteries and 3D images of embryonic hearts and 3D bioprint them with unprecedented resolution and quality out of very soft materials like collagens, alginates and fibrins," said Adam Feinberg, an associate professor at Carnegie Mellon University .

Traditional 3D printers build hard objects typically made of plastic or metal, and they work by depositing material onto a surface layer-by-layer to create the 3D object. Printing each layer requires sturdy support from the layers below, so printing with soft materials like gels has been limited."The challenge with soft materials -think about something like Jello that we eat -is that they collapse under their own weight when 3D printed in air," said Feinberg.

"So we developed a method of printing these soft materials inside a support bath material. Essentially, we print one gel inside of another gel, which allows us to accurately position the soft material as it's being printed, layer-by-layer," he said.

One of the major advances of this technique, termed FRESH, or `Freeform Reversible Embedding of Suspended Hydrogels', is that the support gel can be easily melted away and removed by heating to body temperature. Feinberg's group, has been able to implement their technique on a range of consumerlevel 3D printers, which cost less than $1,000.

3D-printed teeth kills bacteria on contact

Researchers have developed 3D printed teeth and orthodontic braces that can kill bacteria, without causing any harm to human cells.Andreas Herrmann of University of Groningen in the Netherlands and his colleagues have developed an antimicrobial plastic, which allowed them to 3D print teeth that also kill bacteria. "The material can kill bacteria on contact...", said Hermann.

"We've been able to take MRI images of coronary arteries and 3D images of embryonic hearts and 3D bioprint them with unprecedented resolution and quality out of very soft materials like collagens, alginates and fibrins," said Adam Feinberg, an associate professor at Carnegie Mellon University .

Traditional 3D printers build hard objects typically made of plastic or metal, and they work by depositing material onto a surface layer-by-layer to create the 3D object. Printing each layer requires sturdy support from the layers below, so printing with soft materials like gels has been limited."The challenge with soft materials -think about something like Jello that we eat -is that they collapse under their own weight when 3D printed in air," said Feinberg.

"So we developed a method of printing these soft materials inside a support bath material. Essentially, we print one gel inside of another gel, which allows us to accurately position the soft material as it's being printed, layer-by-layer," he said.

One of the major advances of this technique, termed FRESH, or `Freeform Reversible Embedding of Suspended Hydrogels', is that the support gel can be easily melted away and removed by heating to body temperature. Feinberg's group, has been able to implement their technique on a range of consumerlevel 3D printers, which cost less than $1,000.

3D-printed teeth kills bacteria on contact

Researchers have developed 3D printed teeth and orthodontic braces that can kill bacteria, without causing any harm to human cells.Andreas Herrmann of University of Groningen in the Netherlands and his colleagues have developed an antimicrobial plastic, which allowed them to 3D print teeth that also kill bacteria. "The material can kill bacteria on contact...", said Hermann.

Meghna A Singhania is the founder and Editor-in-Chief at Medical Dialogues. An Economics graduate from Delhi University and a post graduate from London School of Economics and Political Science, her key research interest lies in health economics, and policy making in health and medical sector in the country. She is a member of the Association of Healthcare Journalists. She can be contacted at meghna@medicaldialogues.in. Contact no. 011-43720751

Next Story