- Home

- Medical news & Guidelines

- Anesthesiology

- Cardiology and CTVS

- Critical Care

- Dentistry

- Dermatology

- Diabetes and Endocrinology

- ENT

- Gastroenterology

- Medicine

- Nephrology

- Neurology

- Obstretics-Gynaecology

- Oncology

- Ophthalmology

- Orthopaedics

- Pediatrics-Neonatology

- Psychiatry

- Pulmonology

- Radiology

- Surgery

- Urology

- Laboratory Medicine

- Diet

- Nursing

- Paramedical

- Physiotherapy

- Health news

- Fact Check

- Bone Health Fact Check

- Brain Health Fact Check

- Cancer Related Fact Check

- Child Care Fact Check

- Dental and oral health fact check

- Diabetes and metabolic health fact check

- Diet and Nutrition Fact Check

- Eye and ENT Care Fact Check

- Fitness fact check

- Gut health fact check

- Heart health fact check

- Kidney health fact check

- Medical education fact check

- Men's health fact check

- Respiratory fact check

- Skin and hair care fact check

- Vaccine and Immunization fact check

- Women's health fact check

- AYUSH

- State News

- Andaman and Nicobar Islands

- Andhra Pradesh

- Arunachal Pradesh

- Assam

- Bihar

- Chandigarh

- Chattisgarh

- Dadra and Nagar Haveli

- Daman and Diu

- Delhi

- Goa

- Gujarat

- Haryana

- Himachal Pradesh

- Jammu & Kashmir

- Jharkhand

- Karnataka

- Kerala

- Ladakh

- Lakshadweep

- Madhya Pradesh

- Maharashtra

- Manipur

- Meghalaya

- Mizoram

- Nagaland

- Odisha

- Puducherry

- Punjab

- Rajasthan

- Sikkim

- Tamil Nadu

- Telangana

- Tripura

- Uttar Pradesh

- Uttrakhand

- West Bengal

- Medical Education

- Industry

Mixing alginic acid to bone replacement material improves artificial bones: Study

Japan: A new study shows that mixing low viscosity alginic acid with a material commonly used as a bone replacement (called calcium phosphate cement) enhances bone replacement by improving biological interactions. It mixing confers three functional improvements: increased compressive strength, shorter setting time, and acquisition of porosity. The study findings appeared in the Journal of Materials Science: Materials in Medicine.

Calcium phosphate cement (CPC) is used increasingly in recent years owing to its self-setting nature, allowing it to be injected into a patient for a more non-invasive approach. However, one drawback is that CPC has a dense microstructure that makes it difficult for cells to enter. This lack of pores limits the potential for new bone growth.

The study by Akiyoshi Shimatani, Graduate School of Medicine, Osaka City University, Osaka, Japan, and colleagues explores the effect the naturally derived biopolymer alginic acid has on this issue.

Previous research has studied other biopolymers, including gelatin, collagen, and chitosan, but this joint study between the Osaka City University (OCU), Graduate School of Medicine and Graduate School of Engineering has confirmed the positive effects of mixing alginic acid with CPC. In vitro studies showed alginic acid shortens the setting time and increases the compressive strength of CPC. In addition, in vivo studies showed the biopolymer increase porosity of CPC, allowing cells to enter and new bone to grow.

Alginic acid has been widely used in the medical field for procedures such as, cell immobilization, drug delivery, and wound dressing. However, there have been limited studies in conjunction with CPC. The degradability and cross-linking characteristics of alginic acid make it a promising additive to improve on the dense and generally poor mechanical properties of CPC.

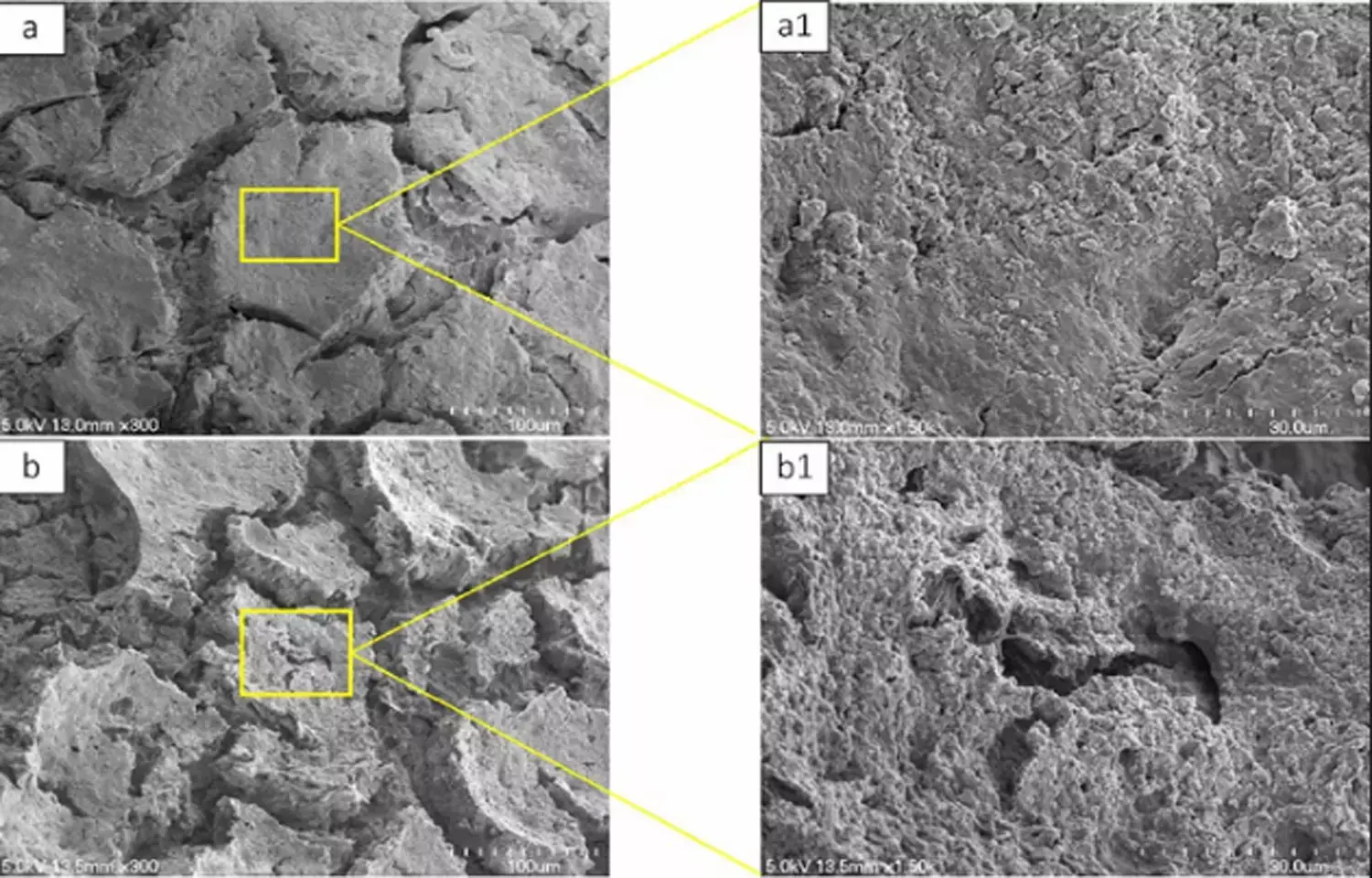

This new study evaluated a series of CPC-alginate (the salt form of alginic acid) compounds with increasing amounts of alginic acid. In vitro, a pH meter showed a decrease in pH levels as alginic acid amounts increased, speeding up setting time. Scanning electron microscopy revealed that compounds with increased alginic acid had more pores and less density. In vivo, X-ray and micro-CT analysis showed that femurs injected with CPC compounds of increased amounts of alginic acid had, after 6 weeks, more degradation and bone formation than the control group.

"Artificial bones can support broken bones, but they do not replace our own bones and remain in the body as a foreign object" said Graduate Student Akiyoshi Shimatani, and first author of the study. Associate Professor Hiromitsu Toyoda of the OCU Dept. of Orthopedic Surgery continued: "To solve this problem, we have developed an artificial bone in collaboration Professor Yoshiyuki Yokogawa and his team from the OCU Faculty of Engineering, which is sticky, hard to break, and replaces the body's own bone. We hope this becomes a new option for artificial bones."

Reference:

The study titled, "A bone replacement-type calcium phosphate cement that becomes more porous in vivo by incorporating a degradable polymer," is published in the journal Journal of Materials Science: Materials in Medicine.

DOI: https://link.springer.com/article/10.1007/s10856-021-06555-1

Hina Zahid Joined Medical Dialogue in 2017 with a passion to work as a Reporter. She coordinates with various national and international journals and association and covers all the stories related to Medical guidelines, Medical Journals, rare medical surgeries as well as all the updates in the medical field. Email: editorial@medicaldialogues.in. Contact no. 011-43720751

Dr Kamal Kant Kohli-MBBS, DTCD- a chest specialist with more than 30 years of practice and a flair for writing clinical articles, Dr Kamal Kant Kohli joined Medical Dialogues as a Chief Editor of Medical News. Besides writing articles, as an editor, he proofreads and verifies all the medical content published on Medical Dialogues including those coming from journals, studies,medical conferences,guidelines etc. Email: drkohli@medicaldialogues.in. Contact no. 011-43720751