- Home

- Medical news & Guidelines

- Anesthesiology

- Cardiology and CTVS

- Critical Care

- Dentistry

- Dermatology

- Diabetes and Endocrinology

- ENT

- Gastroenterology

- Medicine

- Nephrology

- Neurology

- Obstretics-Gynaecology

- Oncology

- Ophthalmology

- Orthopaedics

- Pediatrics-Neonatology

- Psychiatry

- Pulmonology

- Radiology

- Surgery

- Urology

- Laboratory Medicine

- Diet

- Nursing

- Paramedical

- Physiotherapy

- Health news

- Fact Check

- Bone Health Fact Check

- Brain Health Fact Check

- Cancer Related Fact Check

- Child Care Fact Check

- Dental and oral health fact check

- Diabetes and metabolic health fact check

- Diet and Nutrition Fact Check

- Eye and ENT Care Fact Check

- Fitness fact check

- Gut health fact check

- Heart health fact check

- Kidney health fact check

- Medical education fact check

- Men's health fact check

- Respiratory fact check

- Skin and hair care fact check

- Vaccine and Immunization fact check

- Women's health fact check

- AYUSH

- State News

- Andaman and Nicobar Islands

- Andhra Pradesh

- Arunachal Pradesh

- Assam

- Bihar

- Chandigarh

- Chattisgarh

- Dadra and Nagar Haveli

- Daman and Diu

- Delhi

- Goa

- Gujarat

- Haryana

- Himachal Pradesh

- Jammu & Kashmir

- Jharkhand

- Karnataka

- Kerala

- Ladakh

- Lakshadweep

- Madhya Pradesh

- Maharashtra

- Manipur

- Meghalaya

- Mizoram

- Nagaland

- Odisha

- Puducherry

- Punjab

- Rajasthan

- Sikkim

- Tamil Nadu

- Telangana

- Tripura

- Uttar Pradesh

- Uttrakhand

- West Bengal

- Medical Education

- Industry

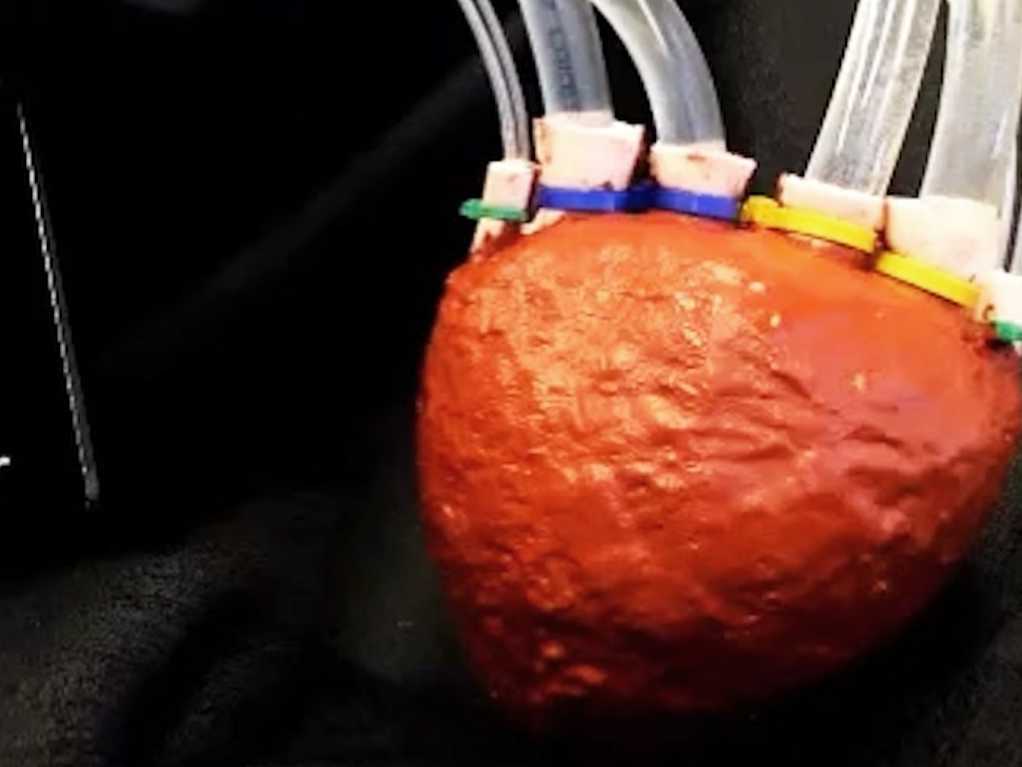

Researchers Create Artificial Foam Heart

NEW YORK: A team from Cornell University has developed an artificial heart with a new lightweight and stretchable foam that has potential for use in prosthetic body parts, artificial organs and soft robotics.

The foam is unique because it can be formed and has connected pores that allow fluids to be pumped through it.

The polymer foam starts as a liquid that can be poured into a mould to create shapes, and because of the pathways for fluids, when air or liquid is pumped through it, the material moves and can change its length by 300 percent.

While applications for use inside the body require federal approval and testing, Cornell researchers are close to making prosthetic body parts with the so-called Â"elastomer foamÂ".

"We are currently pretty far along for making a prosthetic hand this way," said Rob Shepherd, assistant professor of mechanical and aerospace engineering.

The team demonstrated a pump they made into a heart, mimicking both shape and function.

The researchers used carbon fibre and silicone on the outside to fashion a structure that expands at different rates on the surface - to make a spherical shape into an egg shape, for example, that would hold its form when inflated.

"We would like to make the foam actuators faster and with higher strength so we can apply more force. We are also focusing on biocompatibility," Mr Shepherd added in a paper which appeared in the journal Advanced Materials.

The foam is unique because it can be formed and has connected pores that allow fluids to be pumped through it.

The polymer foam starts as a liquid that can be poured into a mould to create shapes, and because of the pathways for fluids, when air or liquid is pumped through it, the material moves and can change its length by 300 percent.

While applications for use inside the body require federal approval and testing, Cornell researchers are close to making prosthetic body parts with the so-called Â"elastomer foamÂ".

"We are currently pretty far along for making a prosthetic hand this way," said Rob Shepherd, assistant professor of mechanical and aerospace engineering.

The team demonstrated a pump they made into a heart, mimicking both shape and function.

The researchers used carbon fibre and silicone on the outside to fashion a structure that expands at different rates on the surface - to make a spherical shape into an egg shape, for example, that would hold its form when inflated.

"We would like to make the foam actuators faster and with higher strength so we can apply more force. We are also focusing on biocompatibility," Mr Shepherd added in a paper which appeared in the journal Advanced Materials.

Meghna A Singhania is the founder and Editor-in-Chief at Medical Dialogues. An Economics graduate from Delhi University and a post graduate from London School of Economics and Political Science, her key research interest lies in health economics, and policy making in health and medical sector in the country. She is a member of the Association of Healthcare Journalists. She can be contacted at meghna@medicaldialogues.in. Contact no. 011-43720751

Next Story